Articles

When a Product is This Revolutionary, There are Bound to be Questions.

Here are FAQs and answers that help break down everything you need to know about how, when and why to use Diesel Injector & DPF Flush.

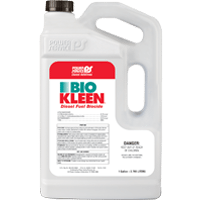

Read MorePower Service Diesel Injector & DPF Flush. Just Pour and Go!

Our new Power Service Diesel Injector & DPF Flush product couldn’t be easier to use. Simply add it to your fuel tank.

Read MoreIntroducing Power Service Diesel Injector & DPF Flush: The Gold Standard for Diesel Performance

Power Service has launched its first new product in almost 20 years: Diesel Injector & DPF Flush. This rapid, single-tank fuel system flush delivers unmatched speed and effectiveness. You’ll notice the results immediately.

Read MoreDiesel Injector & DPF Flush: Pickup Truck Talk Podcast Feature

In a recent episode of Pickup Truck Talk Podcast, our VP of Sales at Power Service introduces our new Diesel Injector & DPF Flush, a dual-action solution designed to reduce regen cycles, improve fuel economy, and help prevent costly emissions repairs.

Read MoreDiesel Injector & DPF Flush: RV News Product Launch Coverage

RV News featured our Diesel Injector & DPF Flush in their latest issue and newsletter! Designed to clean both the injector and DPF system in one step, it’s a powerful solution for restoring diesel performance and reducing maintenance costs.

Read MoreChallenges for Fleet Operators due to the Variability of Diesel Fuel Quality in North America: Winter Operability

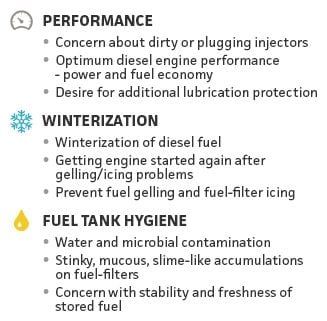

As our world transitions towards cleaner and more sustainable transportation solutions, modern diesel engines are required to operate efficiently for extended periods, consuming more diesel fuel than ever before. This increased fuel consumption places a spotlight on the critical role of diesel fuel quality in ensuring the performance and longevity of these engines. These are some of the specific challenges posed by the variability in diesel fuel quality as it relates to winter operability in North America.

Read MoreWinter’s Bite: Gel and Ice

Iced-up fuel-filters or fuel lines are common in diesel engines when the temperature is very close to 32-degrees. Power Service has an emergency diesel-fuel solution called Diesel 911 and it’s a winter emergency use product specifically designed to get an iced or gelled-up diesel engine back running quickly.

Read MoreProtect Your Diesel Now, Before Winter’s Wrath Turns it Foul

There is simply no way to keep water from contaminating your tank of diesel fuel. Clear-Diesel Fuel & Tank Cleaner polishes your diesel fuel, prevents cold-weather failures, and protects fuel quality over a long, cold winter. Here’s how.

Read MoreWinter Weather and Diesel Fuel: How to Avoid a Breakdown

Diesel fuel has unique properties that provide the power and performance you depend on in your vehicle. But there are crucial differences between it and gasoline that are important to understand in the depths of winter. If you went into a laboratory with instructions to create a liquid fuel capable of providing tremendous low-end torque, high horsepower and the ability to allow a heavy vehicle to cruise efficiently for long distances, you’d emerge with something very similar to diesel fuel swirling around in the lab beaker in your hand. Diesel fuel is a wonder of the modern age that delivers exceptional performance in heavy-duty vehicles – from long-haul Class 8 tractor-trailers to heavy-duty pickup trucks. But those unique properties that give diesel fuel such potency in your engine also come with some substantial differences from gasoline. And it’s important to understand these properties so that you can properly manage them to ensure a long, productive and dependable life for your diesel powertrain. Winter operability of diesel fuel is measured by three primary data points. Let’s go through each one to learn what they are, why they’re important, and what you need to do about each one to ensure proper […]

Read MoreDiesel 911: the number-one emergency-use product for diesels for decades

Proven – by the generations of diesel operators that swear by Diesel 911. Diesel drivers know how quickly things can turn bad when a fuel-filter plugs in cold weather. Fuel-filters plug in winter for two reasons: (1) ice and (2) wax.

Read More