Challenges for Fleet Operators due to the Variability of Diesel Fuel Quality in North America: Winter Operability

Introduction

Modern diesel engines face the dual challenge of meeting ever-increasing emissions and efficiency standards while extending their useful life. However, a critical aspect often overlooked in this interplay is the quality and quantity of diesel fuel consumed throughout a diesel engine’s lifetime.

As our world transitions towards cleaner and more sustainable transportation solutions, modern diesel engines are required to operate efficiently for extended periods, consuming more diesel fuel than ever before. This increased fuel consumption places a spotlight on the critical role of diesel fuel quality in ensuring the performance and longevity of these engines.

In this article, we will detail the specific challenges posed by the variability in diesel fuel quality as it relates to winter operability in North America.

Cold Weather Operability Metrics

Unlike gasoline, diesel fuel contains wax, and in warm weather, that wax exists in liquid form. But as the temperatures drop, the wax begins to thicken and crystallize, eventually blocking the flow of fuel to the engine from the fuel filters, and the engine ceases to operate. To successfully operate a fleet in cold weather, it is important that a fleet manager become familiar with the three main data points that speak to the operability of diesel fuel in cold weather: Cloud Point (CP), Cold-Filter Plugging Point (CFPP) and Pour Point (PP).

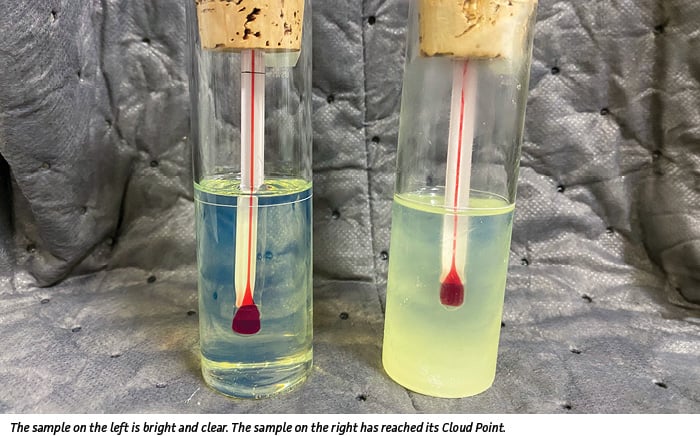

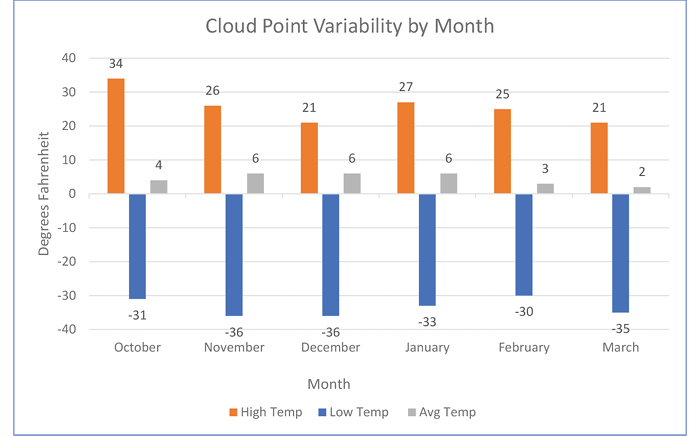

Cloud Point (CP) is the temperature at which wax crystals first begin to solidify and become visible. The fuel will have a cloudy appearance, but it won’t plug fuel filters, at least not yet. A lower CP is more desirable, with the typical range from 32- to 10- degrees Fahrenheit. The diesel fuel will continue to flow from the tank, through the filter, providing power to the engine. Many variables affect the CP of diesel fuel including, but not limited to, location, time of year, crude oil used, and biofuel content. Every batch of diesel fuel can have a different CP and the wide variance can make winter operability hard to predict.

Once the fuel has reached its CP, the wax crystal agglomeration accelerates, veering toward filter blocking and engine shutdown. It is important to know the CP of diesel fuel because the higher the CP, the higher the temperature of engine shutdown.

For winter October 2022 through March of 2023, the Power Service laboratory tested 180 different fuel samples (on average) for Cloud Point per month. As you can see in the chart above, the range of CP’s is significant – from +34- to -31-degrees Fahrenheit. The orange bars show the highest CP for any sample tested in that month. The blue bars show the lowest CP for any sample tested in that month. The gray bars show the average CP across all fuel samples for the month – between 6- and 2-degrees Fahrenheit.

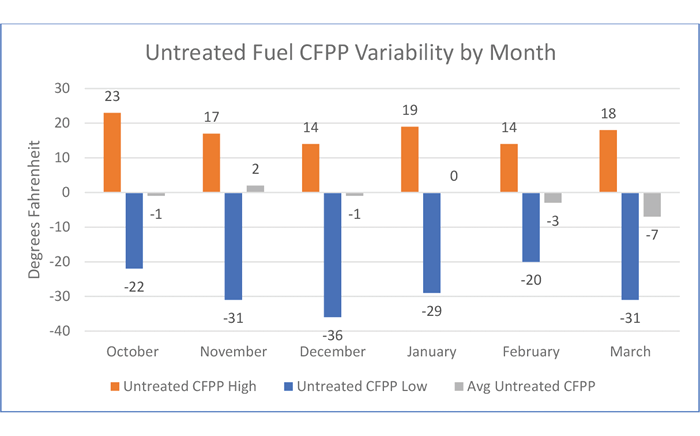

Cold-Filter Plugging Point (CFPP) is the highest temperature at which fuel will stop flowing through a prescribed filter element; the wax crystals have agglomerated and become too large to flow through the filter and the engine stops. This is the most important data point for fleet operators as it speaks directly to the temperature the fleet will cease to operate.

The chart above shows the CFPP of untreated fuel samples for the winter of 2022-2023, from October through March. Just like Cloud Point, there is a significant variance from sample to sample – from +23- to -36-degrees Fahrenheit. The orange bars show the highest CFPP for any untreated sample tested in that month. The blue bars show the lowest CFPP for any untreated sample tested in that month. The gray bars show the average CFPP across all untreated fuel samples for the month – between 2- and -7-degrees Fahrenheit.

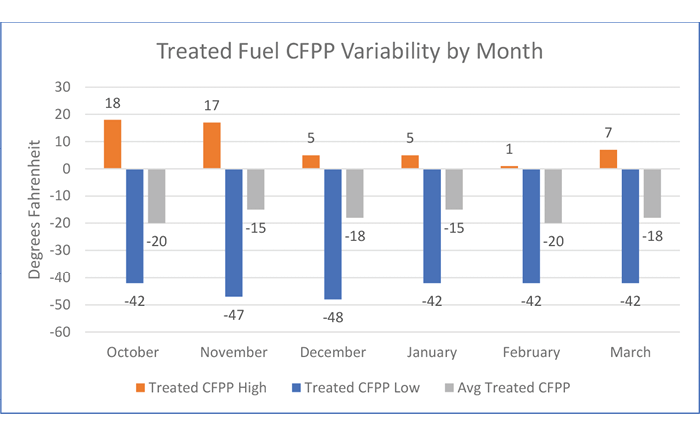

This chart shows the CFPP, by month, for fuel samples that have been treated with Power Service Diesel Fuel Supplement +Cetane Boost. This chart, like the previous two, shows the wide variance of diesel fuel’s cold-weather operability. The orange bars show the highest CFPP for any treated sample tested in that month. The blue bars show the lowest CFPP for any treated sample tested in that month. The gray bars show the average CFPP across all fuel samples for the month – between -15- and -20-degrees Fahrenheit.

Pour Point (PP) is the lowest temperature at which the fuel will still pour. The Pour Point will occur below the CFPP and operability temperature of the fuel. While CFPP is the true measure of operability of diesel fuel in cold weather, the fuel is still liquid and can be poured. When the fuel has reached its PP, it is more likely to be completely frozen solid at this temperature. It is much more difficult to reliquefy a fuel that has reached its PP with Diesel 911 than a fuel that is below its CFPP, but above the PP. Diesel Fuel Supplement +Cetane Boost lowers the PP of diesel fuel as well as the CFPP.

Additives and Winterization

Using additives to winterize diesel fuel is the most common, practical, and cost-effective method for fleet operators to use to provide optimal cold weather performance. Every fleet in North America, large or small, is using something to winterize their diesel fuel. Power Service Diesel Fuel Supplement +Cetane Boost is a diesel fuel antigel that lowers the CFPP of diesel fuel and is the only antigel endorsed by Cummins. Antigels are a kind of fuel additive that are also known as wax crystal modifiers.

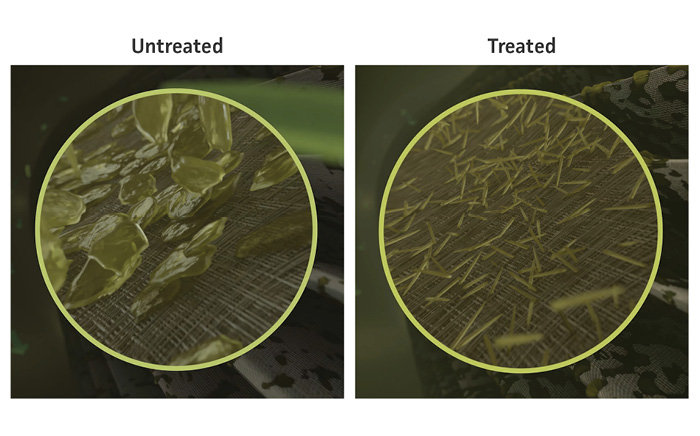

So how does it work? Diesel Fuel Supplement doesn’t prevent wax crystals from forming, that’s not how antigels work. Instead, it works by modifying the shape and size of the wax crystals as they form. In untreated fuel, the crystals form as large, flat sheets of wax that quickly block the flow of fuel through the filter. The wax crystal modifier in Diesel Fuel Supplement changes the shape of the crystals – from large, flat sheets, to small needle-like shapes. They still accumulate on the fuel filter but in a way that allows the diesel fuel to flow past the crystal accumulation at much lower temperatures. (It is very important to note that Diesel Fuel Supplement must be added to the fuel at a temperature above the Cloud Point. Since Diesel Fuel Supplement is changing the shape of the wax crystals, it must be in the fuel before the crystals start to form; it cannot change the shape after they have formed.) Visually the filter of the treated fuel may appear more clogged and coated in waxed than the filter in the untreated fuel, but the haystack-like buildup of the needle-shaped crystals in the treated fuel is more porous. The wax crystal modifier allows the fuel to continue to flow at temperatures much lower than the untreated fuel.

The wax crystals on the left are from an untreated sample and quickly block the flow of fuel from the filter to the engine. The crystals on the right have been treated with the wax crystal modifier in Diesel Fuel Supplement. Fuel can flow past these crystals at much lower temperatures, providing the fleet at least 20 degrees more operability than untreated fuel.

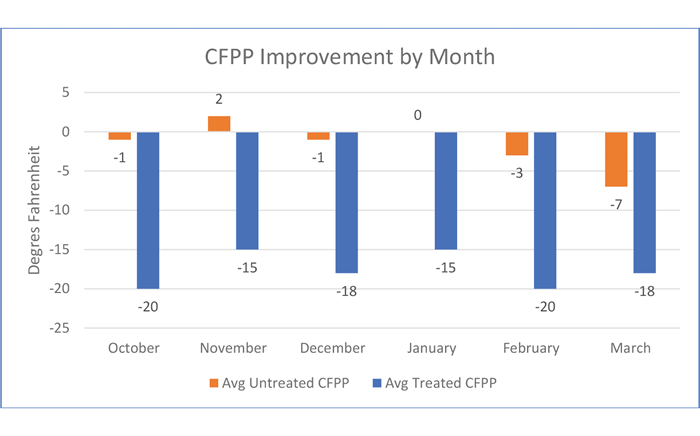

This chart shows the average CFPP of untreated fuel samples for the month, and the subsequent CFPP improvement after those samples were treated with Power Service Diesel Fuel Supplement (DFS). As you can see, fleets treating their fuel with DFS are able to operate trouble-free at temperatures well below 0 degrees Fahrenheit. It is important to note that this chart shows CFPP improvement using a single treat of DFS. A double treatment with DFS will provide additional degrees of operation and is recommended when the ambient temperature is below 0 degrees Fahrenheit or when using biodiesel blends.

When to Use Diesel 911

If any vehicle in a fleet will not start or gain power in cold weather, the fuel needs to be treated with Diesel 911. This is an emergency use product that reliquefies gelled fuel and deices frozen fuel filters to get equipment back on the road quickly. Once the flow of fuel has been restored, it must be treated with Diesel Fuel Supplement to prevent future gelling and icing issues.

Additional Considerations

There are other factors that fleet operators will need to consider for a trouble-free winter:

• Biodiesel Content – Some regions in the U.S. mandate or incentivize the use of biodiesel blends, such as B5 (5% biodiesel) or B20 (20% biodiesel). The best biodiesel feedstocks to use in the winter are soybean or rape seed. Animal fats and tallows are the most problematic. The presence of biodiesel can affect fuel quality and performance. Biodiesel has much higher cloud points (30 – 50 degrees Fahrenheit) than petroleum diesel as well as a much smaller delta between the Cloud Point and Pour Point. Because of this, fuel filters will plug at much higher temperatures than petroleum diesel. Biodiesel blends require a double treatment of Power Service Diesel Fuel Supplement.

• Renewable Diesel – While renewable diesel is made from the same feedstocks as biodiesel, they are chemically different. And although both renewable diesel and petroleum diesel are composed of hydrocarbons, they significantly differ in the distribution and type of hydrocarbons they contain. Petroleum diesel contains a distribution of different sizes of paraffins ranging from 5 carbons long to 30 or more carbons long, while renewable diesel is a homogeneous solution of only one type of paraffin, depending on the feedstock it is produced from. Because of this, it is not responsive to cold flow improving additives of any kind. It is best practice to avoid the use of any renewable diesel in the winter until the technology becomes available that will make it treatable.

• Cetane Improver – Cetane is a measure of the combustion quality of the fuel. Fuels with higher cetane numbers will burn more quickly and completely. The cetane improver in DFS will also provide faster cold starts.

• Lubricity – Despite the prevalence of biodiesel blends, lubricity in Ultra Low Sulfur Diesel (ULSD) fuel for High Pressure Common Rail engines continues to be a concern. DFS contains Slickdiesel Lubricator to protect fuel pumps and injectors from wear caused by low quality fuel.

• Package Handling – The viscosity of diesel fuel antigels increases as temperatures drop. This is compounded as the concentration of an additive increases (more concentrated treatment ratio = requirement for higher storage temperatures.) If the viscosity gets too high, it will become increasingly difficult for the additive to pour out of the bottles and mix properly with the fuel. Always store additives well above the Pour Point of the undiluted additive which will be listed on the Safety Data Sheet (SDS) of the product.

Conclusions

Diesel fuel is the single largest fluid that will run through any fleet, more than engine oil, coolant, etc. These other fluids are consistent. Every bottle of engine oil, coolant, transmission fluid, etc. will contain the exact same liquid. Diesel fuel is the only fluid that has so many variables. Because the fungible fuel distribution and delivery system in North America provides so many opportunities for extreme variances in fuel quality, a well-formulated and consistent additive program should be implemented at all fleets to ensure trouble-free winter operation.

Diesel Fuel Supplement +Cetane Boost

• Endorsed by Cummins for use in diesel engines

• Prevents fuel gelling

• Protects against fuel-filter icing

• Boosts cetane for faster cold starts

• Contains Slickdiesel Lubricator to protect fuel pumps and injectors from increased wear caused by poor quality fuel

• Effective in all diesel fuels, including ULSD and biodiesel blends

• Safe for use in all engines

Diesel 911

• Reliquefies gelled fuel

• De-ices frozen fuel-filters

• Removes water

• Prevents fuel-filter icing

• Contains Slickdiesel Lubricator to protect fuel pumps and injectors from increased wear caused by poor quality fuel

• Effective in all diesel fuels, including ULSD and biodiesel blends

• Safe for use in all engines