Available in: 16-Ounce, 1-Gallon, 55-Gallon Drum, 260-Gallon Tote

Bio Kleen Diesel Fuel Biocide kills microbes in diesel fuel. The dramatically reduced sulfur content in today’s cleaner burning fuels has created ideal opportunities for microbes to grow in fuel tanks. The first indication of microbial contamination is mucous-like accumulations on fuel-filters and increased requirements for fuel-filter replacement. The only way to get rid of microbial contamination is to kill the microbes with a biocide.

Benefits

Benefits

Dual-Phase – effective in both diesel fuel and water

Effective as a “quick-kill” biocide and for long-term diesel fuel maintenance

Kills microbes (bacteria and fungus) that grow in dispersed and free water associated with diesel fuels

Prevents fuel-filter plugging – helps prevent fuel system failures

Protects fuel system components against organic acids created by microbial growth – prevents fuel tank corrosion

Improves fuel performance

Reduces engine maintenance costs

Effective in all diesel fuels, including Ultra Low Sulfur Diesel (ULSD) and biodiesel blends

Safe for use in all diesel engines – does not contain metal or metal ions

Will not void engine manufacturer's warranty when used as directed

Year-Round Maintenance Schedule

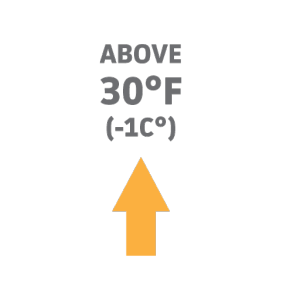

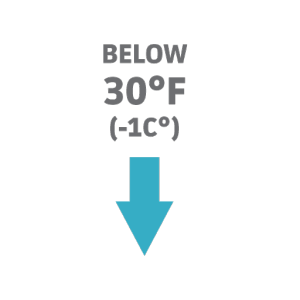

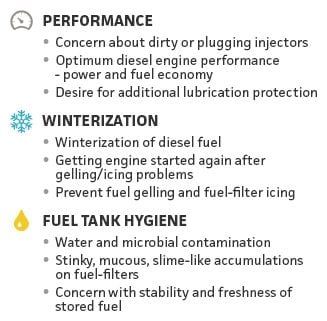

To ensure peak performance of your diesel, Power Service recommends this Year-Round Maintenance Schedule. Check out our video for more information.Every time you fill up

If temperatures are above 30°F., add Diesel Kleen +Cetane Boost (silver bottle) to clean injectors, boost power, lubricate pumps and injectors and restore lost power and fuel economy.Use monthly or as needed

Use this Diesel Injector & DPF Flush to remove injector deposits and reduce emissions & soot build-up in the DPF. It decreases the frequency & duration of both active and passive diesel regens and minimizes forced regens that lead to costly downtime.In a winter emergency

Use Diesel 9•1•1 to reliquify gelled fuel and de-ice frozen fuel-filters if your vehicle will not start or gain power in cold weather.At least quarterly or as needed

Treat with Clear-Diesel Fuel & Tank Cleaner to remove water, disperse contaminants and ensure fuel is stabilized for long-term storage.If microbial contamination is present

Treat with Bio Kleen Diesel Fuel Biocide to kill the microbes and Clear-Diesel Fuel & Tank Cleaner to remove the residual water and contaminants.It is a violation of Federal Law to use this product in a manner inconsistent with the labeling.

This product is to be added to the fuel. DO NOT ADD TO THE DIESEL EXHAUST FLUID TANK.

FOR USE IN HYDROCARBON PRESERVATION To control the growth of problem microorganisms associated with the fuel.In General Use: Add Bio Kleen to storage tanks or fuel tanks for control of microbial growth in diesel oil, fuel oil, gasoline or kerosene. Treatment may be performed by slug dosage or by intermittent metering to maintain a concentration of 135-1,000 ppm of Bio Kleen.

| TREATMENT RATIOS (IN OUNCES) | ||||

|---|---|---|---|---|

| BIO KLEEN BIOCIDE DOSE | SHOCK TREATMENT | PPM IN FUEL (APPROX) | MAINTENANCE TREATMENT | PPM IN FUEL (APPROX) |

| 1 Ounce | 20 Gallons | 390 | 55 Gallons | 142 |

| 16 Ounces | 320 Gallons | 390 | 880 Gallons | 142 |

| 128 Ounces (1 Gallon) | 2,500 Gallons | 400 | 7,000 Gallons | 142 |

In A Fuel-Treatment Pre-Mix: Bio Kleen may be mixed with other fuel additive for addition to fuel. The end user must add sufficient Bio Kleen to the pre-mix to provide 135-1,000 ppm of Bio Kleen in the treated fuel.

For Storage In Tanks Without Intentional Water: Add 0.125-1 gallon of Bio Kleen directly to each 1,000 gallons of hydrocarbon in the system to obtain a concentration of approximately 135-1,000 ppm.

For Storage Above Water: Add 1 gallon of Bio Kleen to each 1,000 gallons of water in the bulk storage system to achieve a concentration of approximately 1,000 ppm. To facilitate mixing, dissolve each gallon of Bio Kleen in 100 gallons of water and add this solution directly to the water phase in the tank with minimal agitation.

Customer Reviews

Write a Review

Did You Know?

Ultra Low Sulfur Diesel (ULSD) fuel has more problems with microbial contamination than previous higher sulfur fuels. Since ULSD can no longer carry water dissolved in solution, more water is shedding to the bottom of fuel tanks, creating a life-support system and breeding ground for microbes. Parrafin content has increased as sulfur and aromatics decrease, providing a major food source to microbes. Additionally, sulfur is a natural poison to bacteria and fungus and its reduction has further exacerbated microbial contamination problems in ULSD.

Product Details

Available in: 16-Ounce, 1-Gallon, 55-Gallon Drum, 260-Gallon Tote

Bio Kleen Diesel Fuel Biocide kills microbes in diesel fuel. The dramatically reduced sulfur content in today’s cleaner burning fuels has created ideal opportunities for microbes to grow in fuel tanks. The first indication of microbial contamination is mucous-like accumulations on fuel-filters and increased requirements for fuel-filter replacement. The only way to get rid of microbial contamination is to kill the microbes with a biocide.

Benefits

Dual-Phase – effective in both diesel fuel and water

Effective as a “quick-kill” biocide and for long-term diesel fuel maintenance

Kills microbes (bacteria and fungus) that grow in dispersed and free water associated with diesel fuels

Prevents fuel-filter plugging – helps prevent fuel system failures

Protects fuel system components against organic acids created by microbial growth – prevents fuel tank corrosion

Improves fuel performance

Reduces engine maintenance costs

Effective in all diesel fuels, including Ultra Low Sulfur Diesel (ULSD) and biodiesel blends

Safe for use in all diesel engines – does not contain metal or metal ions

Will not void engine manufacturer's warranty when used as directed

Year-Round Maintenance Schedule

To ensure peak performance of your diesel, Power Service recommends this Year-Round Maintenance Schedule. Check out our video for more information.Every time you fill up

If temperatures are above 30°F., add Diesel Kleen +Cetane Boost (silver bottle) to clean injectors, boost power, lubricate pumps and injectors and restore lost power and fuel economy.Use monthly or as needed

Use this Diesel Injector & DPF Flush to remove injector deposits and reduce emissions & soot build-up in the DPF. It decreases the frequency & duration of both active and passive diesel regens and minimizes forced regens that lead to costly downtime.In a winter emergency

Use Diesel 9•1•1 to reliquify gelled fuel and de-ice frozen fuel-filters if your vehicle will not start or gain power in cold weather.At least quarterly or as needed

Treat with Clear-Diesel Fuel & Tank Cleaner to remove water, disperse contaminants and ensure fuel is stabilized for long-term storage.If microbial contamination is present

Treat with Bio Kleen Diesel Fuel Biocide to kill the microbes and Clear-Diesel Fuel & Tank Cleaner to remove the residual water and contaminants.Product Directions

It is a violation of Federal Law to use this product in a manner inconsistent with the labeling.

This product is to be added to the fuel. DO NOT ADD TO THE DIESEL EXHAUST FLUID TANK.

FOR USE IN HYDROCARBON PRESERVATION To control the growth of problem microorganisms associated with the fuel.In General Use: Add Bio Kleen to storage tanks or fuel tanks for control of microbial growth in diesel oil, fuel oil, gasoline or kerosene. Treatment may be performed by slug dosage or by intermittent metering to maintain a concentration of 135-1,000 ppm of Bio Kleen.

| TREATMENT RATIOS (IN OUNCES) | ||||

|---|---|---|---|---|

| BIO KLEEN BIOCIDE DOSE | SHOCK TREATMENT | PPM IN FUEL (APPROX) | MAINTENANCE TREATMENT | PPM IN FUEL (APPROX) |

| 1 Ounce | 20 Gallons | 390 | 55 Gallons | 142 |

| 16 Ounces | 320 Gallons | 390 | 880 Gallons | 142 |

| 128 Ounces (1 Gallon) | 2,500 Gallons | 400 | 7,000 Gallons | 142 |

In A Fuel-Treatment Pre-Mix: Bio Kleen may be mixed with other fuel additive for addition to fuel. The end user must add sufficient Bio Kleen to the pre-mix to provide 135-1,000 ppm of Bio Kleen in the treated fuel.

For Storage In Tanks Without Intentional Water: Add 0.125-1 gallon of Bio Kleen directly to each 1,000 gallons of hydrocarbon in the system to obtain a concentration of approximately 135-1,000 ppm.

For Storage Above Water: Add 1 gallon of Bio Kleen to each 1,000 gallons of water in the bulk storage system to achieve a concentration of approximately 1,000 ppm. To facilitate mixing, dissolve each gallon of Bio Kleen in 100 gallons of water and add this solution directly to the water phase in the tank with minimal agitation.

Customer Reviews

Customer Reviews

Write a Review

Part #/Treatment Chart

Recommended With

Recommended With

Clear-Diesel Fuel & Tank Cleaner

An advanced diesel fuel and tank cleaner.

The Fuel Polishing Formula of Clear-Diesel Fuel & Tank Cleaner removes water and slime, disperses contaminants and stabilizes fuel during long-term storage.

View ProductVoice of the Customer

From The Learning Center

From the Learning Center

About Biodiesel and Biodiesel Blends

As pressure increases to lessen America’s dependence on fossil fuels, biodiesel will become more widely used as a blended component of diesel fuel. Some states have mandated that all diesel fuels contain varying percentages of biodiesel, and the U.S. government has authorized a B20 fuel (20% biodiesel and 80% diesel fuel) for use in non-strategic applications. Poor cold weather performance, high water content and microbial infestation will require biodiesel fuels to be treated for reliable performance. All Power Service diesel additives are effective in treating biodiesel and biodiesel blends and have directions for their use printed on the back of the containers.

View ArticleDid You Know?

Ultra Low Sulfur Diesel (ULSD) fuel has more problems with microbial contamination than previous higher sulfur fuels. Since ULSD can no longer carry water dissolved in solution, more water is shedding to the bottom of fuel tanks, creating a life-support system and breeding ground for microbes. Parrafin content has increased as sulfur and aromatics decrease, providing a major food source to microbes. Additionally, sulfur is a natural poison to bacteria and fungus and its reduction has further exacerbated microbial contamination problems in ULSD.

Recommended With

Clear-Diesel Fuel & Tank Cleaner

An advanced diesel fuel and tank cleaner.

The Fuel Polishing Formula of Clear-Diesel Fuel & Tank Cleaner removes water and slime, disperses contaminants and stabilizes fuel during long-term storage.

View ProductFrom the Learning Center

About Biodiesel and Biodiesel Blends

As pressure increases to lessen America’s dependence on fossil fuels, biodiesel will become more widely used as a blended component of diesel fuel. Some states have mandated that all diesel fuels contain varying percentages of biodiesel, and the U.S. government has authorized a B20 fuel (20% biodiesel and 80% diesel fuel) for use in non-strategic applications. Poor cold weather performance, high water content and microbial infestation will require biodiesel fuels to be treated for reliable performance. All Power Service diesel additives are effective in treating biodiesel and biodiesel blends and have directions for their use printed on the back of the containers.

View Article