Detergent / Injector Deposits (IDIDs, Nozzle Coking)

Detergents are integral to optimal diesel fuel and diesel engine operation, especially when it comes to injector deposits.

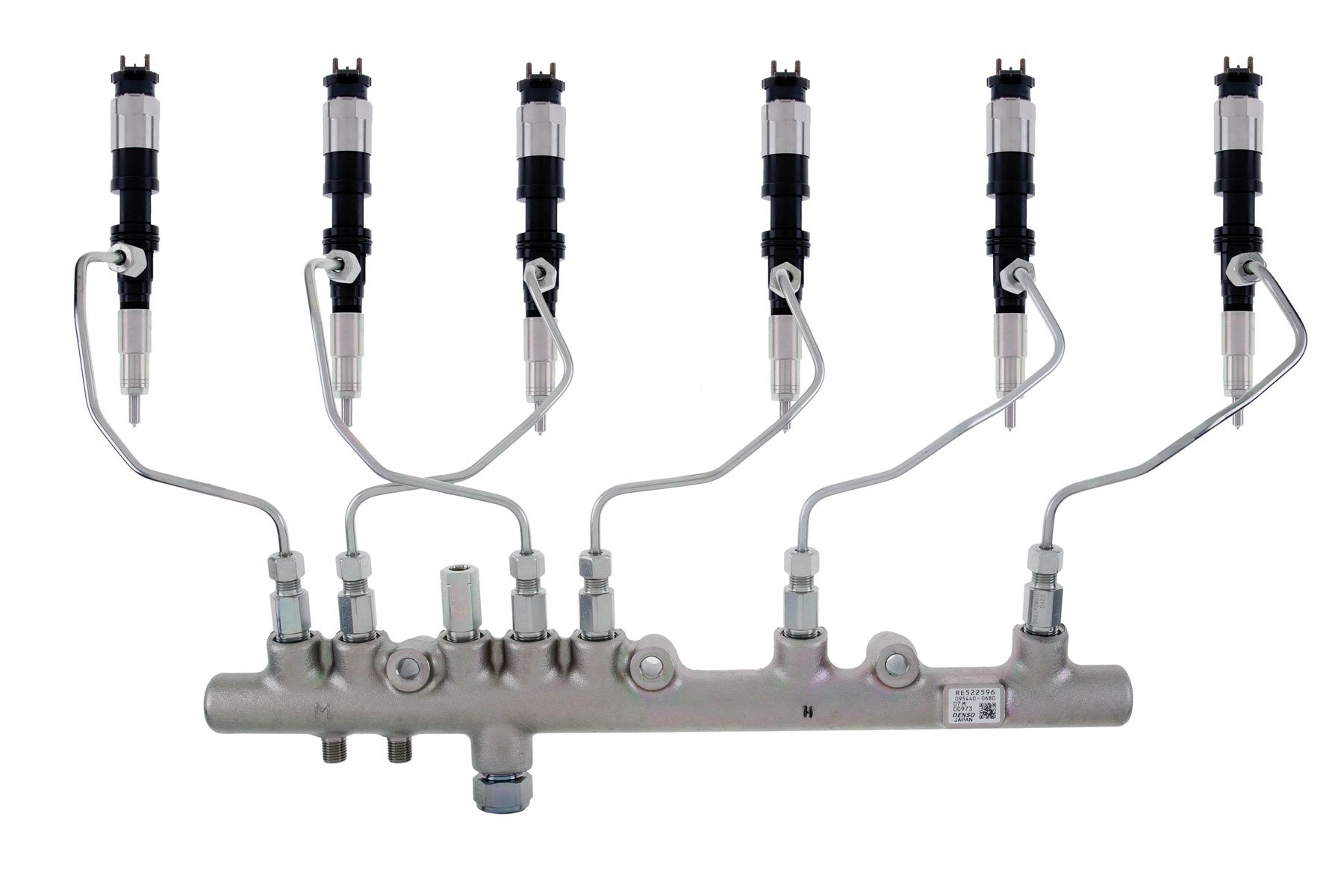

There are 2 types of injector deposits: the newer Internal Diesel Injector Deposits (IDIDs) and conventional external deposits (nozzle coking) that have been around for a long time. IDIDs form deep inside the internal metal surfaces of injectors, where they are subjected to the extreme heat and pressures inside today’s High Pressure Common Rail (HPCR) injection systems. HPCR injectors are highly sophisticated – they operate at extremely high temperatures; tolerances within the injector are 1 to 3 microns and experience pressures up to 30,000 PSI.

When deposits form, the injector will stick and disrupt flow into the combustion chamber. If the injector sticks open, excess fuel can end up in the cylinder resulting in increased emissions, decreased fuel economy and excessive power loss. If the injector sticks closed, the resulting insufficient amount of fuel leads to power loss and a rough-running engine. External deposits form on the injector tip to impede nozzle spray patterns and reduce combustion efficiency.

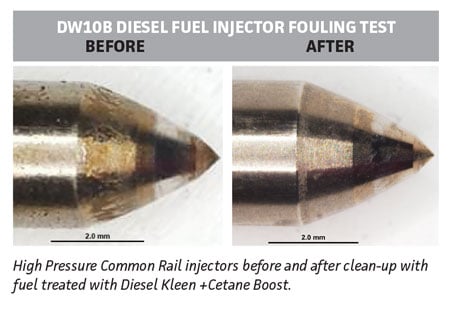

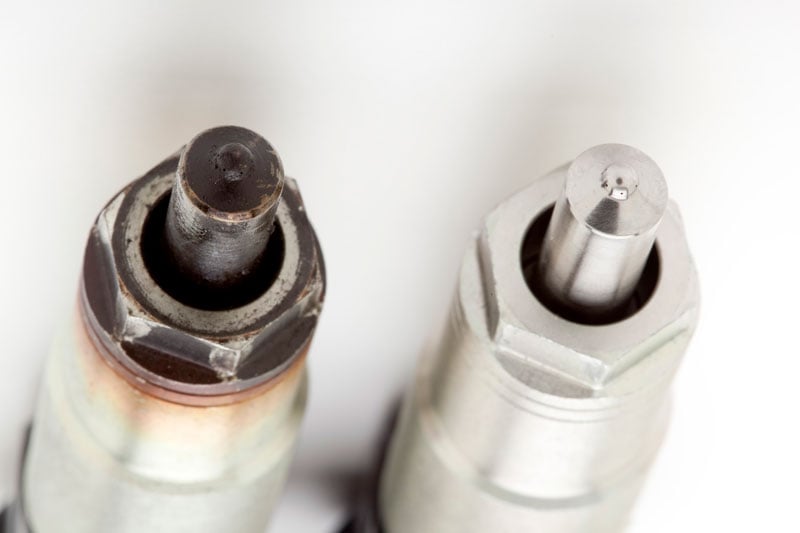

Significant external deposits can be seen on the injector on the left. Ongoing use of Diesel Kleen will clean up dirty injectors and prevent future deposit build-up as seen on the injector on the right.

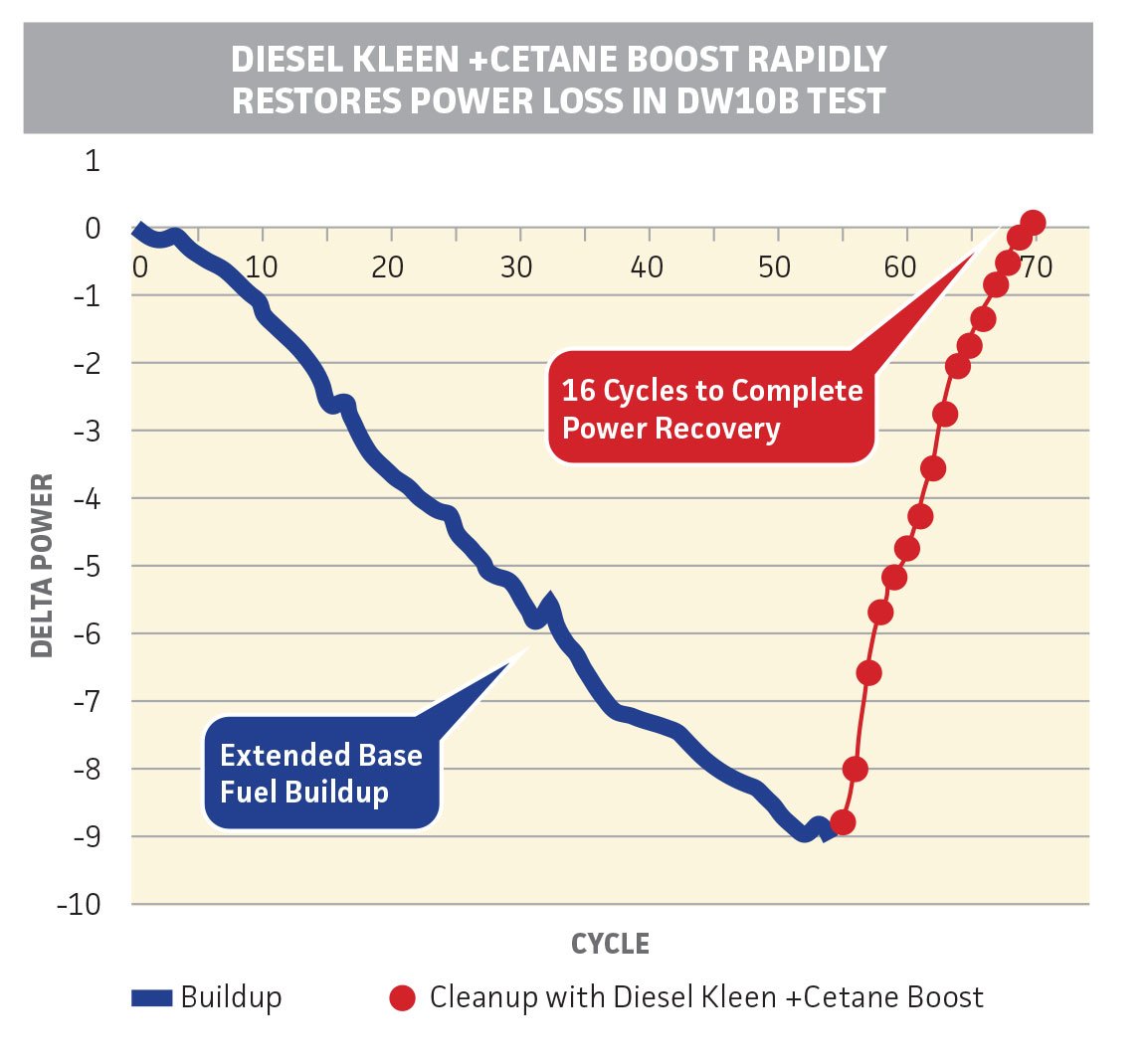

These deposits can be removed and prevented with the detergent technology in Diesel Kleen +Cetane Boost. The engine test developed to replicate the in-field issues experienced by Original Engine Manufacturers (OEMs) with IDIDs is the DW10B Diesel Fuel Injector Fouling Test. It uses a high intensity timed test cycle to measure the percentage power loss with the formation of IDIDs and the recovery time required to remove them. This test provides a benchmark for evaluating the effectiveness of detergents to both prevent and rapidly remove IDIDs.

Diesel Kleen +Cetane Boost has obtained the highest rating while providing accelerated Clean-Up levels of detergent performance in all industry standard diesel injector deposit tests, including: DW10B, DW10C and XUD9. Numerous field trials have shown the significant benefits of the detergent in Diesel Kleen, including thermal stability protection to prevent asphaltenes from plugging fuel-filters, improving the filterability of both asphaltenes and monoglycerides found in diesel fuel (ASTM D2068 Filter Blocking Tendency Test) and protecting against corrosion with an A rating in the NACE Corrosion Test. Diesel Kleen +Cetane Boost restores lost power and fuel economy up to 7%. It is also the only fuel injector cleaner endorsed by Cummins, the largest manufacturer of diesel engines in the world.

Fuel Economy

Operating at maximum fuel economy is always a high-priority goal, but even more so when fuel prices are at all-time highs. Reduction in fuel economy occurs over time as deposits form on the injection system. These can come in the form of conventional external injector deposits (nozzle coking) or internal diesel injector deposits (IDIDs) in today’s modern High Pressure Common Rail (HPCR) injection systems. HPCR injectors are highly sophisticated – they operate at extremely high temperatures; tolerances within the injector are 1 to 3 microns and experience pressures up to 30,000 PSI. When deposits form, the injector will stick and disrupt flow into the combustion chamber. If the injector sticks open, excess fuel can end up in the cylinder resulting in increased emissions, decreased fuel economy and excessive power loss. If the injector sticks closed, the resulting insufficient amount of fuel leads to power loss and a rough-running engine. External deposits form on the injector tip to impede nozzle spray patterns and reduce combustion efficiency.

Thermal instability and asphaltenes can also form deposits on injectors and fuel-filters. The hydro-treating process used by refiners to remove sulfur to produce ULSD (Ultra Low Sulfur Diesel) fuel that is mandated for use in the US decreases the natural anti-oxidation properties of the fuel, causing it to become unstable when exposed to extreme heat.

Thermal instability and asphaltenes can also form deposits on injectors and fuel-filters. The hydro-treating process used by refiners to remove sulfur to produce ULSD (Ultra Low Sulfur Diesel) fuel that is mandated for use in the US decreases the natural anti-oxidation properties of the fuel, causing it to become unstable when exposed to extreme heat.

HPCR injection systems operate in extreme heat conditions, sometimes in excess of 350°F., causing the thermally unstable fuel to darken, form sediments and solid deposits that cause fuel-filter plugging and injector sticking. Long-term storage and thermal instability can also cause the formation of asphaltenes. Asphaltenes are naturally occurring organic hydrocarbons found in diesel fuel that positively contribute to the fuel’s BTU value. Extreme heat causes the asphaltenes to agglomerate and fall out of suspension, resulting in black carbon (soot) formations on fuel-filters and leads to deposits on injectors.

Reduction in fuel economy also occurs when the fuel is not completely burned during the combustion process. Cetane is a high energy compound that improves overall combustion. Cetane number is a measure of the ignition quality of diesel fuel – the higher the cetane number, the shorter the ignition delay. Fuels with higher cetane numbers ignite more quickly and burn more completely, resulting in smoother running engines with less power lag, reduced emissions, more power and improved fuel economy.

Using a high-quality diesel fuel additive that contains both detergents and cetane improver is imperative to maintaining and restoring lost fuel economy. The synergy between these components removes and prevents injection system deposits and provides for more complete combustion of the diesel fuel. Diesel Kleen +Cetane Boost utilizes a powerful detergent and cetane improver to smooth rough-running engines, boost power, reduce downshifting and power lag and restores lost power and fuel economy up to 7%. It is also the only fuel injector cleaner endorsed by Cummins, the largest manufacturer of diesel engines in the world.

Fuel Economy

Operating at maximum fuel economy is always a high-priority goal, but even more so when fuel prices are at all-time highs. Reduction in fuel economy occurs over time as deposits form on the injection system. These can come in the form of conventional external injector deposits (nozzle coking) or internal diesel injector deposits (IDIDs) in today’s modern High Pressure Common Rail (HPCR) injection systems. HPCR injectors are highly sophisticated – they operate at extremely high temperatures; tolerances within the injector are 1 to 3 microns and experience pressures up to 30,000 PSI. When deposits form, the injector will stick and disrupt flow into the combustion chamber. If the injector sticks open, excess fuel can end up in the cylinder resulting in increased emissions, decreased fuel economy and excessive power loss. If the injector sticks closed, the resulting insufficient amount of fuel leads to power loss and a rough-running engine. External deposits form on the injector tip to impede nozzle spray patterns and reduce combustion efficiency.

Thermal instability and asphaltenes can also form deposits on injectors and fuel-filters. The hydro-treating process used by refiners to remove sulfur to produce ULSD (Ultra Low Sulfur Diesel) fuel that is mandated for use in the US decreases the natural anti-oxidation properties of the fuel, causing it to become unstable when exposed to extreme heat.

Thermal instability and asphaltenes can also form deposits on injectors and fuel-filters. The hydro-treating process used by refiners to remove sulfur to produce ULSD (Ultra Low Sulfur Diesel) fuel that is mandated for use in the US decreases the natural anti-oxidation properties of the fuel, causing it to become unstable when exposed to extreme heat.

HPCR injection systems operate in extreme heat conditions, sometimes in excess of 350°F., causing the thermally unstable fuel to darken, form sediments and solid deposits that cause fuel-filter plugging and injector sticking. Long-term storage and thermal instability can also cause the formation of asphaltenes. Asphaltenes are naturally occurring organic hydrocarbons found in diesel fuel that positively contribute to the fuel’s BTU value. Extreme heat causes the asphaltenes to agglomerate and fall out of suspension, resulting in black carbon (soot) formations on fuel-filters and leads to deposits on injectors.

Reduction in fuel economy also occurs when the fuel is not completely burned during the combustion process. Cetane is a high energy compound that improves overall combustion. Cetane number is a measure of the ignition quality of diesel fuel – the higher the cetane number, the shorter the ignition delay. Fuels with higher cetane numbers ignite more quickly and burn more completely, resulting in smoother running engines with less power lag, reduced emissions, more power and improved fuel economy.

Using a high-quality diesel fuel additive that contains both detergents and cetane improver is imperative to maintaining and restoring lost fuel economy. The synergy between these components removes and prevents injection system deposits and provides for more complete combustion of the diesel fuel. Diesel Kleen +Cetane Boost utilizes a powerful detergent and cetane improver to smooth rough-running engines, boost power, reduce downshifting and power lag and restores lost power and fuel economy up to 7%. It is also the only fuel injector cleaner endorsed by Cummins, the largest manufacturer of diesel engines in the world.

Cetane

Cetane is a high energy compound that improves overall combustion. Cetane number is a measure of the ignition quality of diesel fuel – the higher the cetane number, the shorter the ignition delay. Fuels with higher cetane numbers ignite more quickly and burn more completely, resulting in smoother running engines with less power lag, reduced emissions, more power and improved fuel economy. Additionally, since unburned fuel that leaves the combustion chamber as exhaust becomes trapped in the DPF (diesel particulate filter) and leads to more frequent regens, burning more of the fuel and improving the overall combustion process will lead to fewer regens.

The EMA (Engine Manufacturers Association) states, “Fuels with low cetane numbers will cause hard starting, rough operation, noise and exhaust smoke. Generally, diesel engines will operate better on fuels with cetane numbers above 50.” The laboratory at Power Service tests thousands of diesel fuel samples every year and reports that the average cetane number of Ultra Low Sulfur Diesel (ULSD) fuel is between 47 and 48. Diesel Kleen +Cetane Boost boosts cetane up to 6 numbers and will meet the EMA target of 50 in most fuels. It smooths rough-running engines, boosts power, reduces downshifting and power lag and restores lost power and fuel economy up to 7%. It is also the only fuel injector cleaner endorsed by Cummins, the largest manufacturer of diesel engines in the world.

Lubricity

Modern diesel engines rely on diesel fuel to lubricate fuel injectors and pumps in both High Pressure Common Rail (HPCR) and older legacy systems. Without proper lubrication, the components of these systems, with tolerances of 2-3 microns, are subjected to increased wear and premature failure, resulting in costly repairs.

In 2006 the EPA mandated the introduction of Ultra Low Sulfur Diesel (ULSD) fuel with a maximum sulfur content of 15 parts per million (ppm). To remove sulfur and aromatics from diesel fuel, refiners use a process called hydro-treating. In addition to removing sulfur, this process also removes many of the nitrogen and polar compounds that provide natural lubricating properties in diesel fuel.

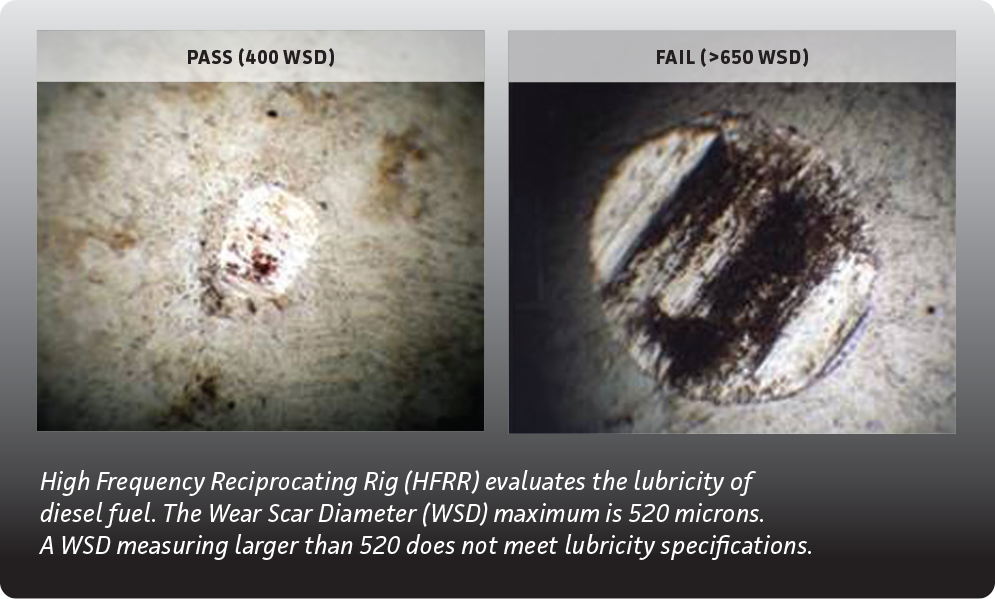

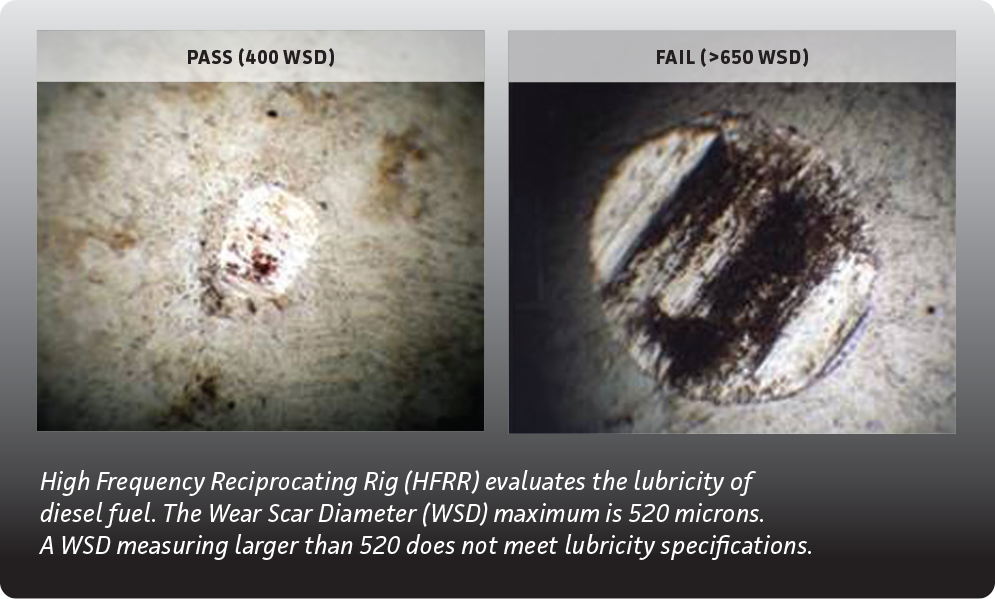

The High Frequency Reciprocating Rig (HFRR – ASTM 6079) test is the industry standard to measure the lubricity of diesel fuel – the lower the number, the better the lubrication properties of the fuel. The test requires a maximum 520-micron wear scar diameter (WSD) as the specification for diesel fuel. The EMA (Engine Manufacturers Association) recommends a maximum WSD specification of 460.

Slickdiesel Lubricator is a proprietary Power Service lubricity improver in Diesel Kleen +Cetane Boost. It exceeds the HFRR specification of 520 WSD and allows operators to achieve the EMA recommendation of 460 WSD in most fuels. It protects pumps and injectors from increased wear rates caused by ULSD, providing maximum protection to optimize performance and avoid costly repairs. Power Service Diesel Fuel Supplement +Cetane Boost and Diesel 911 also contain Slickdiesel Lubricator to protect injection systems.

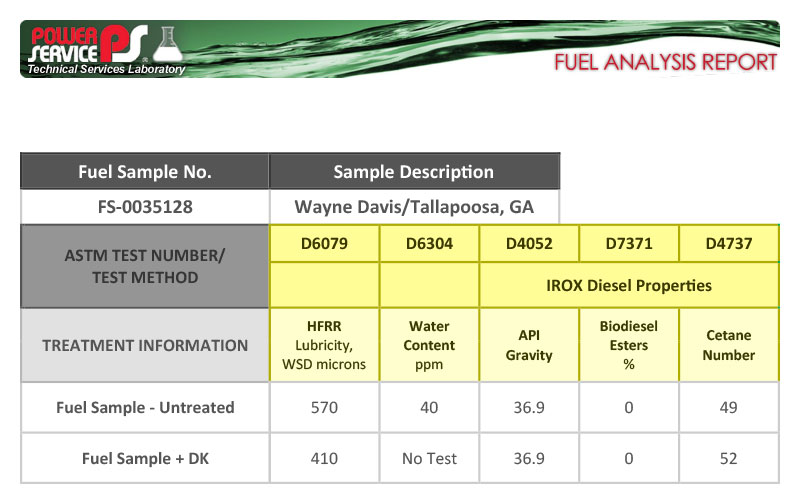

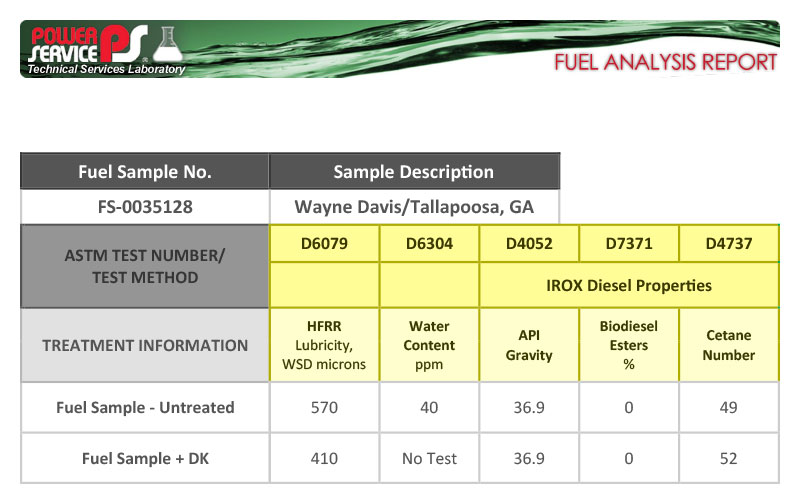

Fuel Analysis Report from the Power Service Technical Services Laboratory – shows a 160 improvement in Wear Scar Diameter from the untreated fuel to fuel treated with Diesel Kleen.

Lubricity

Modern diesel engines rely on diesel fuel to lubricate fuel injectors and pumps in both High Pressure Common Rail (HPCR) and older legacy systems. Without proper lubrication, the components of these systems, with tolerances of 2-3 microns, are subjected to increased wear and premature failure, resulting in costly repairs.

In 2006 the EPA mandated the introduction of Ultra Low Sulfur Diesel (ULSD) fuel with a maximum sulfur content of 15 parts per million (ppm). To remove sulfur and aromatics from diesel fuel, refiners use a process called hydro-treating. In addition to removing sulfur, this process also removes many of the nitrogen and polar compounds that provide natural lubricating properties in diesel fuel.

The High Frequency Reciprocating Rig (HFRR – ASTM 6079) test is the industry standard to measure the lubricity of diesel fuel – the lower the number, the better the lubrication properties of the fuel. The test requires a maximum 520-micron wear scar diameter (WSD) as the specification for diesel fuel. The EMA (Engine Manufacturers Association) recommends a maximum WSD specification of 460.

Slickdiesel Lubricator is a proprietary Power Service lubricity improver in Diesel Kleen +Cetane Boost. It exceeds the HFRR specification of 520 WSD and allows operators to achieve the EMA recommendation of 460 WSD in most fuels. It protects pumps and injectors from increased wear rates caused by ULSD, providing maximum protection to optimize performance and avoid costly repairs. Power Service Diesel Fuel Supplement +Cetane Boost and Diesel 911 also contain Slickdiesel Lubricator to protect injection systems.

Fuel Analysis Report from the Power Service Technical Services Laboratory – shows a 160 improvement in Wear Scar Diameter from the untreated fuel to fuel treated with Diesel Kleen.

Fuel Stability (Thermal, Asphaltenes)

The hydro-treating process used by refiners to remove sulfur to produce ULSD (Ultra Low Sulfur Diesel) fuel that is mandated for use in the US decreases the natural anti-oxidation properties of the fuel, causing it to become unstable when exposed to extreme heat. Today’s High Pressure Common Rail (HPCR) injection systems operate in extreme heat conditions, sometimes in excess of 350F., causing the thermally unstable fuel to darken, form sediments and solid deposits that cause fuel-filter plugging and injector sticking.

Long-term storage and thermal instability can also cause the formation of asphaltenes. Asphaltenes are naturally occurring organic hydrocarbons found in diesel fuel that positively contribute to the fuel’s BTU value. Extreme heat causes the asphaltenes to agglomerate and fall out of suspension, resulting in black carbon (soot) formations on fuel-filters and leads to deposits on injectors. In worst-case scenarios, they can completely coat the fuel tank and fuel system, leading to costly repairs.

Long-term storage and thermal instability can also cause the formation of asphaltenes. Asphaltenes are naturally occurring organic hydrocarbons found in diesel fuel that positively contribute to the fuel’s BTU value. Extreme heat causes the asphaltenes to agglomerate and fall out of suspension, resulting in black carbon (soot) formations on fuel-filters and leads to deposits on injectors. In worst-case scenarios, they can completely coat the fuel tank and fuel system, leading to costly repairs.

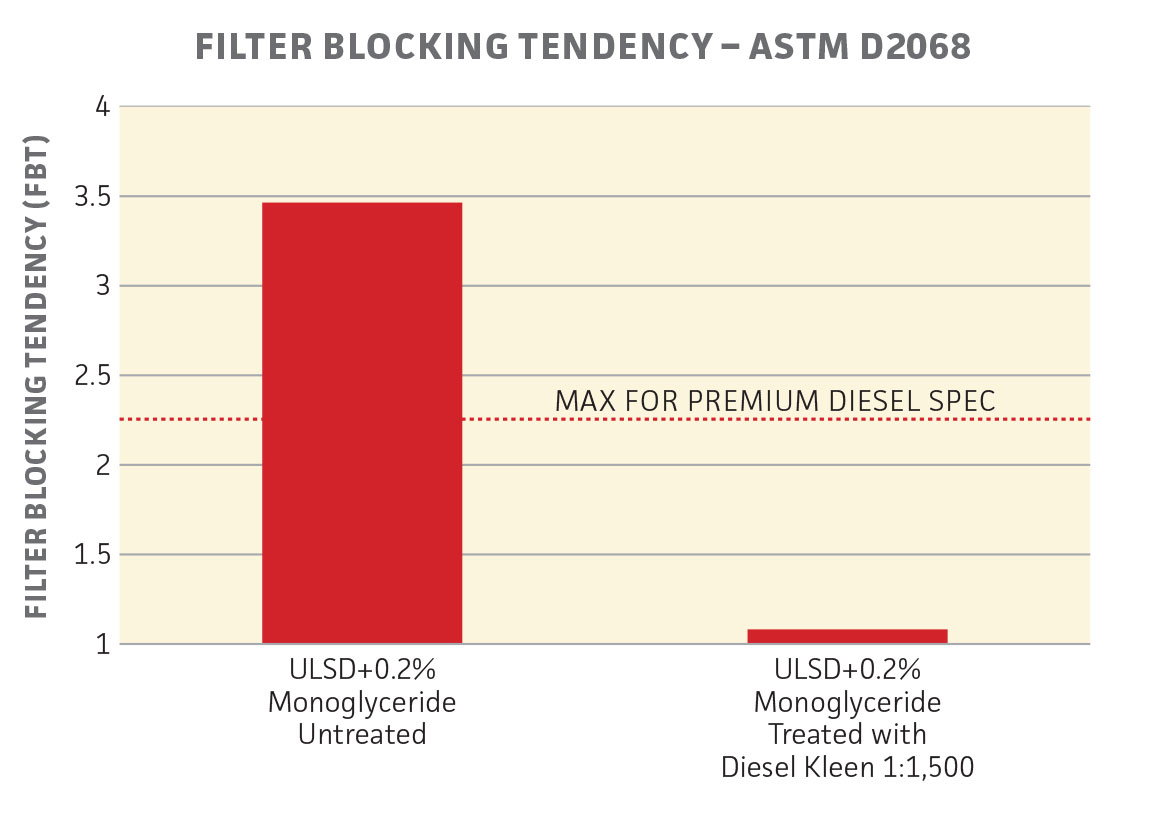

Diesel Kleen +Cetane Boost contains powerful detergents that prevent the formation and agglomeration of asphaltenes and thermal breakdown of diesel fuel. It protects against sludge formations that plug fuel-filters and injectors. The ASTM D2068 Filter Blocking Tendency (FBT) test measures a fuel’s ability to filter asphaltenes and monoglycerides. Diesel Kleen +Cetane Boost provides filterability performance well below the maximum specification of 2.25 for premium diesel fuel. It is also the only fuel injector cleaner endorsed by Cummins, the largest manufacturer of diesel engines in the world.

Year-Round Maintenance Schedule

To ensure peak performance of your diesel, Power Service recommends this Year-Round Maintenance Schedule. Check out our video for more information.

Every time you fill up

If temperatures are above 30°F., add Diesel Kleen +Cetane Boost (silver bottle) to clean injectors, boost power, lubricate pumps and injectors and restore lost power and fuel economy.

If temperatures are below 30°F., add Diesel Fuel Supplement +Cetane Boost (white bottle) for winter operability. It prevents fuel gelling and protects against fuel-filter icing.

In a winter emergency

Use Diesel 9•1•1 to reliquify gelled fuel and de-ice frozen fuel-filters if your vehicle will not start or gain power in cold weather.

At least quarterly or as needed

Treat with Clear-Diesel Fuel & Tank Cleaner to remove water, disperse contaminants and ensure fuel is stabilized for long-term storage.

If microbial contamination is present

Treat with Bio Kleen Diesel Fuel Biocide to kill the microbes and Clear-Diesel Fuel & Tank Cleaner to remove the residual water and contaminants.