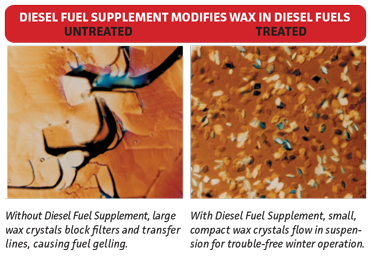

Prevent Fuel Gelling

Diesel fuel antigels, also know as cold-flow improvers, are used to prevent fuel gelling in diesel equipment and storage tanks. As diesel fuel cools, wax precipitates out of the fuel, plugging fuel-filters and ultimately preventing fuel from reaching the engine. Diesel Fuel Supplement +Cetane Boost modifies the size and shape of the wax crystals so they remain small enough to flow through fuel-filters without plugging.

Cold-Weather Operability Testing

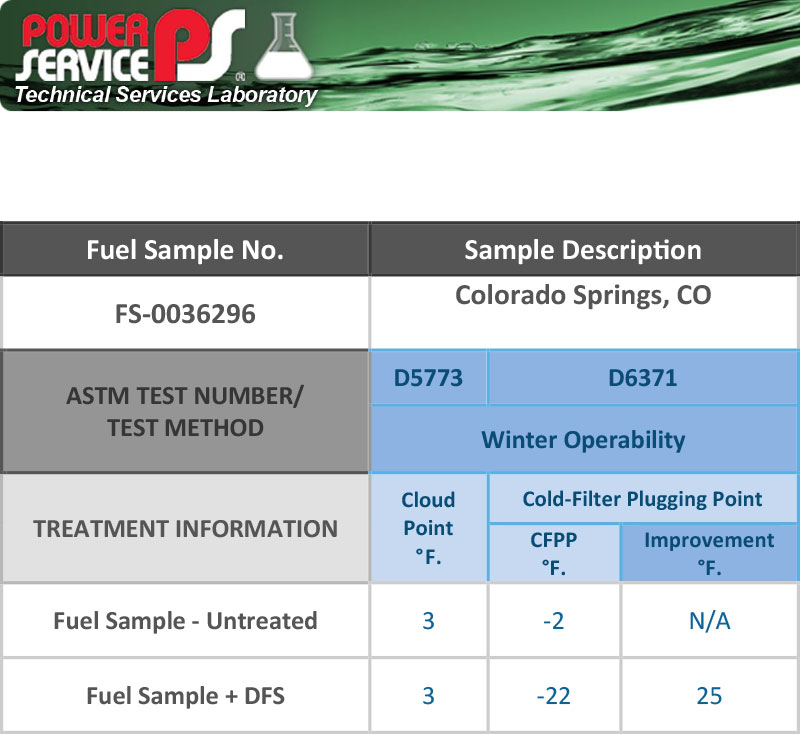

The Power Service laboratory tests tens of thousands of fuel samples every year using industry-standard ASTM test methods to ensure that our antigel or cold-flow technology is industry-leading and robust enough to treat a broad cross-section of fuels, even at extreme cold temperatures. These tests are: (1) Cloud Point, (2) Cold-Filter Plugging Point (CFPP) and (3) Pour Point.

The Power Service laboratory tests tens of thousands of fuel samples every year using industry-standard ASTM test methods to ensure that our antigel or cold-flow technology is industry-leading and robust enough to treat a broad cross-section of fuels, even at extreme cold temperatures. These tests are: (1) Cloud Point, (2) Cold-Filter Plugging Point (CFPP) and (3) Pour Point.

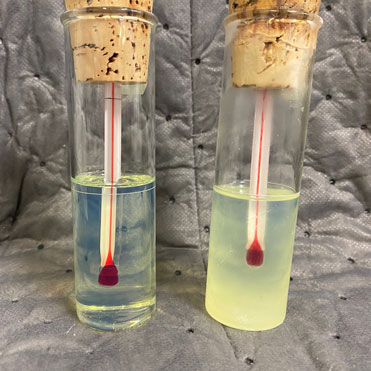

The Cloud Point of diesel fuel is the temperature when wax crystals first appear as the fuel is cooled. The wax crystals turn the fuel hazy. The fuel is still liquid and will not plug a fuel-filter. The Cloud Point of diesel fuel can vary from -30°F. to +30°F. depending on the geographic location, time of the year, refinery, crude slate and biodiesel content. A lower Cloud Point is preferable in the winter since fuels with lower cloud points have less wax than fuels with higher cloud points and will perform better at lower temperatures. It is important to note that antigels, such as Diesel Fuel Supplement +Cetane Boost, must be added to the fuel at a temperature higher than the fuel’s Cloud Point to be effective.

Cold-Filter Plugging Point or CFPP of a fuel is the temperature at which a fuel will no longer flow through a prescribed fuel-filter because the wax crystals have agglomerated and become too large to flow through the fuel-filter. CFPP is the best measure to predict the low temperature operability of diesel fuel. Untreated No. 2 diesel fuels will typically have a CFPP of 3° to 5°F. below the Cloud Point. For example, an untreated fuel with a 10°F. Cloud Point, will typically have a CFPP of 5 to 7°F. Fuels treated with Power Service Diesel Fuel Supplement typically result in a CFPP of at least 15°F. to 20°F. below the Cloud Point, with many fuels significantly exceeding that mark. In extreme cold, when temperatures drop below 0°F., or when using biodiesel blends, it is recommended to use a double treatment of Diesel Fuel Supplement.

Cold-Filter Plugging Point or CFPP of a fuel is the temperature at which a fuel will no longer flow through a prescribed fuel-filter because the wax crystals have agglomerated and become too large to flow through the fuel-filter. CFPP is the best measure to predict the low temperature operability of diesel fuel. Untreated No. 2 diesel fuels will typically have a CFPP of 3° to 5°F. below the Cloud Point. For example, an untreated fuel with a 10°F. Cloud Point, will typically have a CFPP of 5 to 7°F. Fuels treated with Power Service Diesel Fuel Supplement typically result in a CFPP of at least 15°F. to 20°F. below the Cloud Point, with many fuels significantly exceeding that mark. In extreme cold, when temperatures drop below 0°F., or when using biodiesel blends, it is recommended to use a double treatment of Diesel Fuel Supplement.

The Pour Point is the temperature at which the fuel will not pour; it is no longer a liquid and has gelled or frozen into a solid. The Pour Point is not a measure of a fuel’s operability but is used by pipelines to determine when a fuel can be moved.

Power Service tests tens of thousands of fuel samples every year. This is an actual Fuel Analysis Report from our lab showing 25 more degrees of winter operability for the fuel treated with Diesel Fuel Supplement compared to the same fuel that is untreated.

Beyond the Testing

Additional considerations for low temperature operability of diesel fuel are that of blending No. 1 and No. 2 diesel, biodiesel and biodiesel blends, and the presence of water.

If the CFPP of a fuel is not low enough for the temperatures in a specific region, suppliers may blend No. 2 diesel with No. 1 diesel to lower the Cloud Point. For every 10% of No. 1 diesel fuel blended, the Cloud Point will typically lower 2°F. to 3°F. While blending does provide improved low temperature operability, it does have downsides as well. No. 1 diesel fuel lowers the energy content of the fuel and users will experience decreased fuel economy and power. Today’s Ultra Low Sulfur Diesel (ULD) fuels have reduced lubricity and because No. 1 diesel has even less lubricity, blending with No. 1 diesel requires supplemental lubrication. No. 1 diesel is also less soluble with biodiesel than No. 2 and can cause increased wax precipitation. Additionally, blending is expensive and sourcing No. 1 diesel has become increasingly challenging in the winter.

Biodiesel

While the use of biodiesel and biodiesel blends has certain benefits, they are notoriously challenging to use in low temperature environments. It is not uncommon for a biodiesel sample to have a Cloud Point of up to 50°F. They can also raise the Cloud Point of No. 2 diesel in concentrations as low as 5%. Water is much more soluble in biodiesel at warmer temperatures and less soluble at lower temperatures. This means that water absorbed when it is warm will fall out of suspension when temperatures drop, causing free water to accumulate on tank bottoms. When using biodiesel blends in low temperature environments, a double treatment of Diesel Fuel Supplement should be used.

Biodiesel

While the use of biodiesel and biodiesel blends has certain benefits, they are notoriously challenging to use in low temperature environments. It is not uncommon for a biodiesel sample to have a Cloud Point of up to 50°F. They can also raise the Cloud Point of No. 2 diesel in concentrations as low as 5%. Water is much more soluble in biodiesel at warmer temperatures and less soluble at lower temperatures. This means that water absorbed when it is warm will fall out of suspension when temperatures drop, causing free water to accumulate on tank bottoms. When using biodiesel blends in low temperature environments, a double treatment of Diesel Fuel Supplement should be used.

Year-Round Maintenance Schedule

To ensure peak performance of your diesel, Power Service recommends this Year-Round Maintenance Schedule. Check out our video for more information.

Every time you fill up

If temperatures are above 30°F., add Diesel Kleen +Cetane Boost (silver bottle) to clean injectors, boost power, lubricate pumps and injectors and restore lost power and fuel economy.

If temperatures are below 30°F., add Diesel Fuel Supplement +Cetane Boost (white bottle) for winter operability. It prevents fuel gelling and protects against fuel-filter icing.

In a winter emergency

Use Diesel 9•1•1 to reliquify gelled fuel and de-ice frozen fuel-filters if your vehicle will not start or gain power in cold weather.

At least quarterly or as needed

Treat with Clear-Diesel Fuel & Tank Cleaner to remove water, disperse contaminants and ensure fuel is stabilized for long-term storage.

If microbial contamination is present

Treat with Bio Kleen Diesel Fuel Biocide to kill the microbes and Clear-Diesel Fuel & Tank Cleaner to remove the residual water and contaminants.