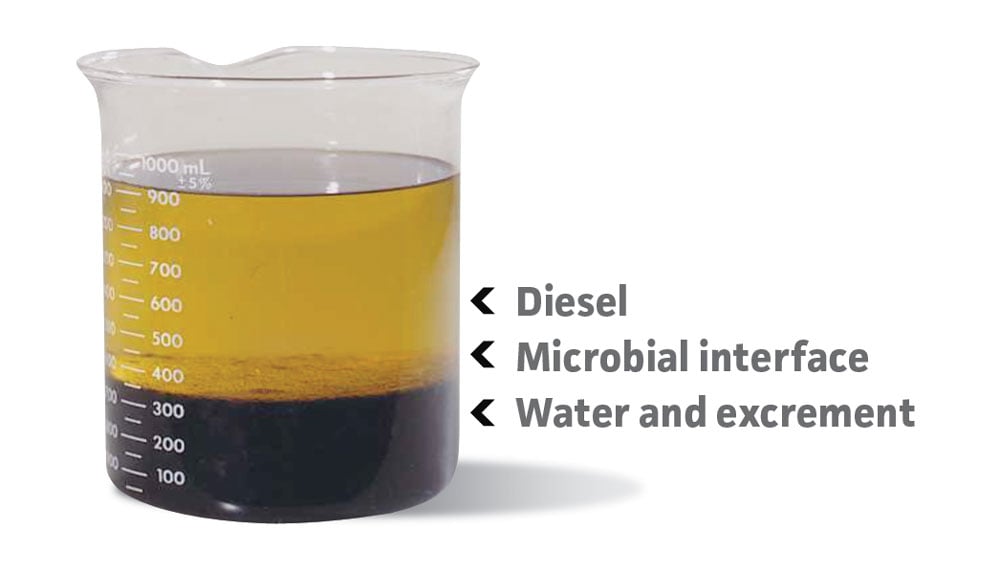

Microbial/Algae Contamination

The number-one issue that our customers reach out to us about is fuel tank hygiene, specifically microbial, commonly referred to as “algae,” contamination. Optimal diesel performance starts with a clean tank.

Ultra Low Sulfur Diesel (USLD) fuels contain a maximum of 15 parts per million (ppm) of sulfur and are more prone to contamination. Sulfur acts as a natural poison to microbes (bacteria and fungus). Fuels with lower sulfur content provide a less hostile environment in which the microbes can flourish. Sulfur dissolves and carries water out of fuel systems. ULSD fuels can no longer carry water dissolved in solution, so more water is shedding to the bottom of fuel tanks—creating a life support system and breeding ground for microbes. Additionally, moisture is produced within fuel tanks via condensation (heating and cooling), thermal changes and humidity. Also, diesel fuels blended with biodiesel contain higher levels of water than standard 100 percent petro-diesel, contributing further to the accumulation of water in diesel fuel storage systems. And biodiesel is a food source for microbes.

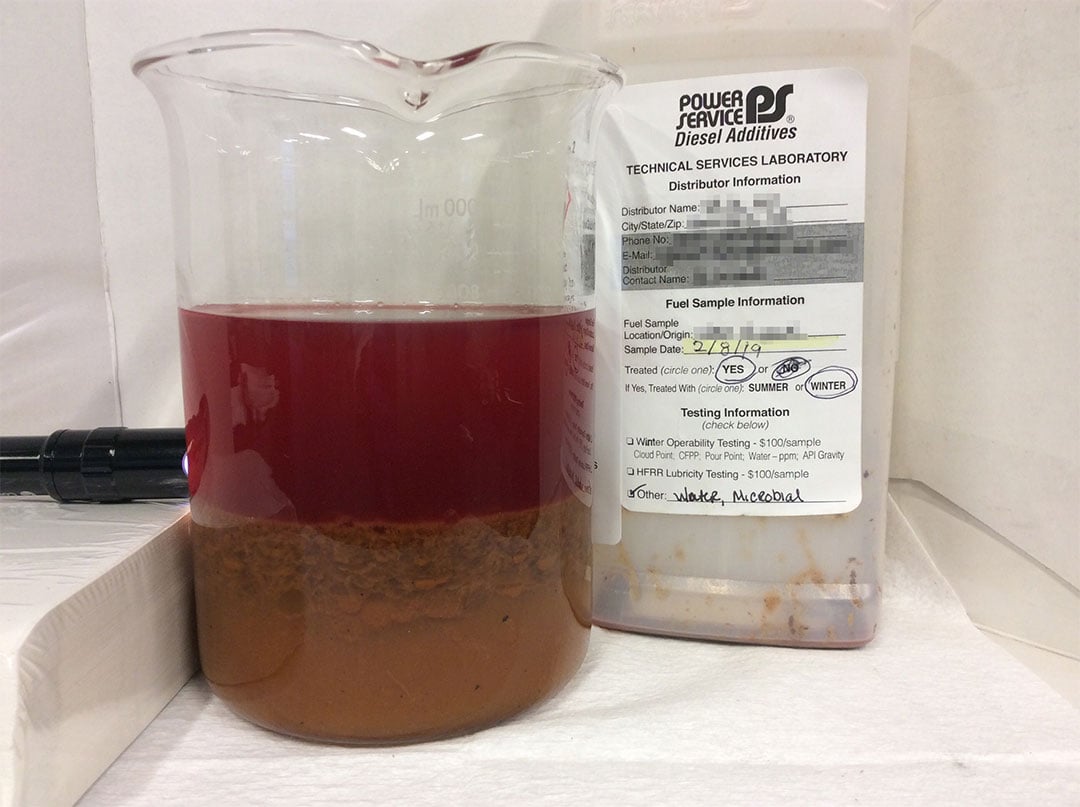

Premature fuel-filter plugging usually is the first sign of microbial contamination. Microbes invade the water on tank bottoms and become established in as little as one to two months. They grow on all interior surfaces of the fuel tank and encase themselves in their own excrement, seen on fuel-filters as a slimy, black or brown mucous-like substance. The excrement is acidic and causes tank corrosion that can lead to failure of pumps, level-detection devices and tank leakage.

The Power Service laboratory tests thousands of fuel samples every year for sulfur content, water content, biodiesel content and microbial contamination. We regularly counsel our customers on how to remove their active contamination and how to prevent future contaminations from occurring.

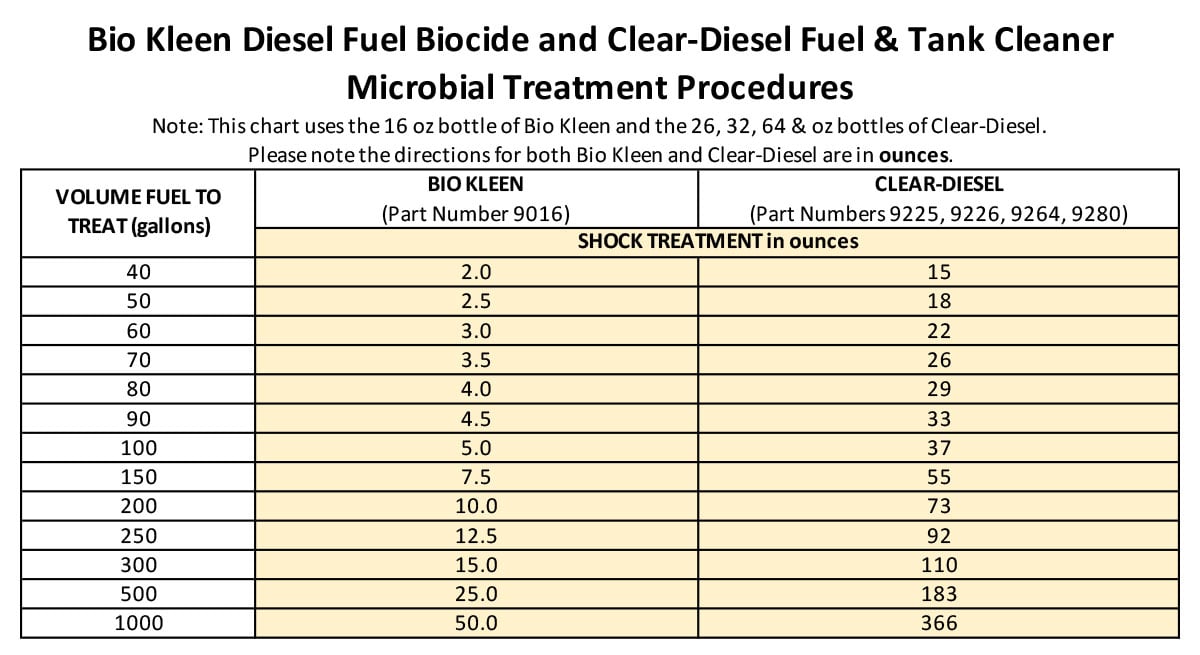

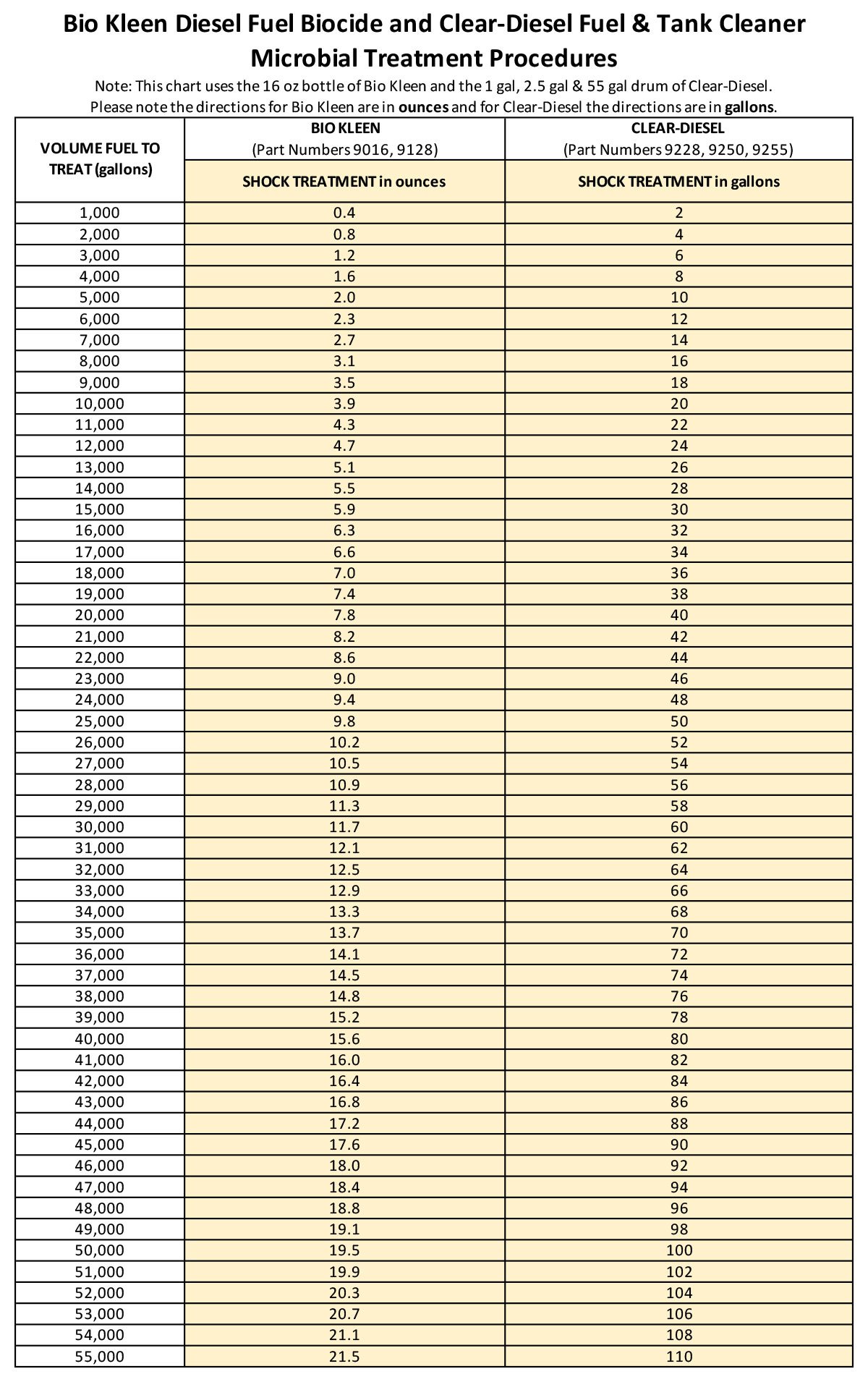

Microbial contamination treatment procedures require the use of two Power Service diesel fuel additives. Bio Kleen Diesel Fuel Biocide is a dual-phase (effective in both diesel fuel and water) pesticide that kills the microbes. Dual-phase biocides are recommended by OEMs for their effectiveness. Clear-Diesel Fuel & Tank Cleaner should be used with Bio Kleen to provide the most effective kill. While Bio Kleen kills the microbes, Clear-Diesel cleans the fuel tanks by dispersing both the water and the excrement, exposing the microbes to the biocide for a faster and more effective kill and reduces subsequent fuel-filter plugging.

Keeping a fuel tank clean and dry is the best way to prevent a microbial contamination from forming. Clear-Diesel is an advanced diesel fuel and tank cleaning technology. It removes water, disperses fuel contaminants and stabilizes fuel during long-term storage.

Prevent Microbial Contamination

Keeping a fuel tank clean and dry is the best way to prevent a microbial contamination from forming. Clear-Diesel Fuel & Tank Cleaner is an advanced diesel fuel and tank cleaning technology. It removes water, disperses fuel contaminants and stabilizes fuel during long-term storage.

The Power Service laboratory tests thousands of fuel samples every year for sulfur content, water content, biodiesel content and microbial contamination. We regularly counsel our customers on how to remove their active contamination and how to prevent future contaminations from occurring.

Prevent Microbial Contamination

Keeping a fuel tank clean and dry is the best way to prevent a microbial contamination from forming. Clear-Diesel Fuel & Tank Cleaner is an advanced diesel fuel and tank cleaning technology. It removes water, disperses fuel contaminants and stabilizes fuel during long-term storage.

The Power Service laboratory tests thousands of fuel samples every year for sulfur content, water content, biodiesel content and microbial contamination. We regularly counsel our customers on how to remove their active contamination and how to prevent future contaminations from occurring.

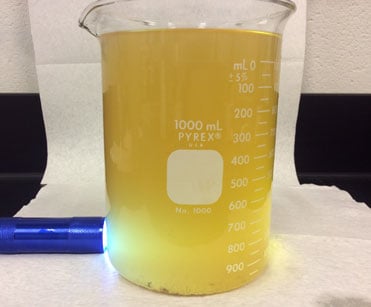

Actual customer contaminated fuel sample

Water

Water always has been a problem in diesel fuel, but the problems have never been more rampant than with Ultra Low Sulfur (ULSD) fuel. Sulfur dissolves and carries water out of fuel systems. ULSD fuels can no longer carry water dissolved in solution so more water is shedding to the bottom of fuel tanks, creating a life-support system and breeding ground for microbes. Additionally, moisture is produced within fuel tanks via condensation (heating and cooling), thermal changes and humidity. Also, diesel fuels blended with biodiesel contain higher levels of water than standard 100 percent petro-diesel, contributing further to the accumulation of water in diesel fuel storage systems.

Regular use of Clear-Diesel Fuel & Tank Cleaner (at least quarterly or as needed) removes water, disperses contaminants and stabilizes fuel during long-term storage. Optimal diesel performance starts with a clean tank.

Water also creates challenges for winter operability.

Elevated amounts of water in diesel fuel are problematic year-round, but especially during low temperature operating conditions. No. 2 diesel fuel usually carries 30 to 60 parts per million (ppm) of water in solution. The dissolved water causes no problems, and the fuel will be completely clear and bright. A fuel that has a water content higher than 30 to 60 ppm is at risk of fuel-filter icing at 32°F. as water freezes and accumulates on the fuel-filters. Adding Clear-Diesel Fuel & Tank Cleaner before temperatures drop below freezing will prevent fuel-filter icing.

Long-Term Fuel Storage

Diesel fuel deteriorates when stored for more than 90 days through thermal and oxidative processes. The chemical changes that occur result in the formation of both fuel-soluble polymers and fuel-insoluble materials such as gums and particulates. Acids also can be generated by fuel oxidation.

Long-term storage and thermal instability also can cause the formation of asphaltenes. Asphaltenes are naturally occurring organic hydrocarbons found in diesel fuel that positively contribute to the fuel’s BTU value. Extreme heat causes the asphaltenes to agglomerate and fall out of suspension, resulting in black carbon (soot) formations on fuel-filters and leading to deposits on injectors. In worst-case scenarios, they can completely coat the fuel tank and fuel system—leading to costly repairs.

+PetroFresh stabilizes fuel for long-term storage. It keeps fuel residues dispersed and diesel fuel fresh when stored up to 12-18 months. Fuel tanks stay cleaner and fuel-filters will last longer, providing cost savings and operational efficiencies. Optimal diesel performance starts with a clean tank.

Long-Term Fuel Storage

Diesel fuel deteriorates when stored for more than 90 days through thermal and oxidative processes. The chemical changes that occur result in the formation of both fuel-soluble polymers and fuel-insoluble materials such as gums and particulates. Acids also can be generated by fuel oxidation.

Long-term storage and thermal instability also can cause the formation of asphaltenes. Asphaltenes are naturally occurring organic hydrocarbons found in diesel fuel that positively contribute to the fuel’s BTU value. Extreme heat causes the asphaltenes to agglomerate and fall out of suspension, resulting in black carbon (soot) formations on fuel-filters and leading to deposits on injectors. In worst-case scenarios, they can completely coat the fuel tank and fuel system—leading to costly repairs.

+PetroFresh stabilizes fuel for long-term storage. It keeps fuel residues dispersed and diesel fuel fresh when stored up to 12-18 months. Fuel tanks stay cleaner and fuel-filters will last longer, providing cost savings and operational efficiencies. Optimal diesel performance starts with a clean tank.

Biodiesel

Water always has been a problem in diesel fuel, but the problems have never been more rampant than with Ultra Low Sulfur (ULSD) fuel and biodiesel. Sulfur dissolves and carries water out of fuel systems. ULSD fuels can no longer carry water dissolved in solution so more water is shedding to the bottom of fuel tanks, creating a life-support system and breeding ground for microbes. Diesel fuels blended with biodiesel contain higher levels of water than standard 100 percent petro-diesel, contributing further to the accumulation of water in diesel fuel storage systems. And, biodiesel is a food source for microbes. In winter, fuels with a water content higher than 30 to 60 parts per million (ppm) are at risk of fuel-filter icing at 32°F. as water freezes and accumulates on the fuel-filters.

Regular use of Clear-Diesel Fuel & Tank Cleaner (at least quarterly or as needed) removes water, disperses contaminants and stabilizes fuel during long-term storage, especially when using biodiesel blends. Adding Clear-Diesel in the fall is part of a good winter-prep to remove the water and prevent fuel-filter icing. Optimal diesel performance starts with a clean tank.

Year-Round Maintenance Schedule

To ensure peak performance of your diesel, Power Service recommends this Year-Round Maintenance Schedule. Check out our video for more information.

Every time you fill up

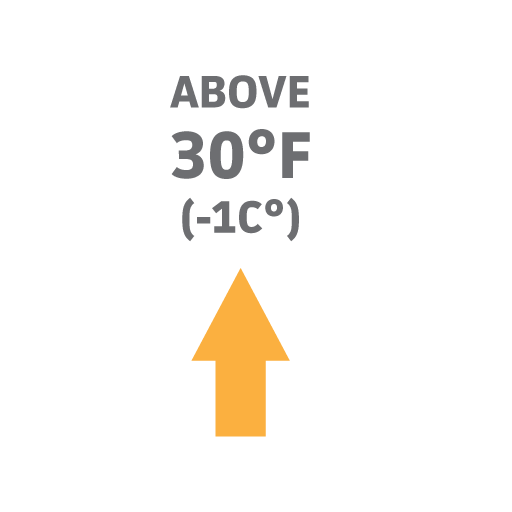

If temperatures are above 30°F., add Diesel Kleen +Cetane Boost (silver bottle) to clean injectors, boost power, lubricate pumps and injectors and restore lost power and fuel economy.

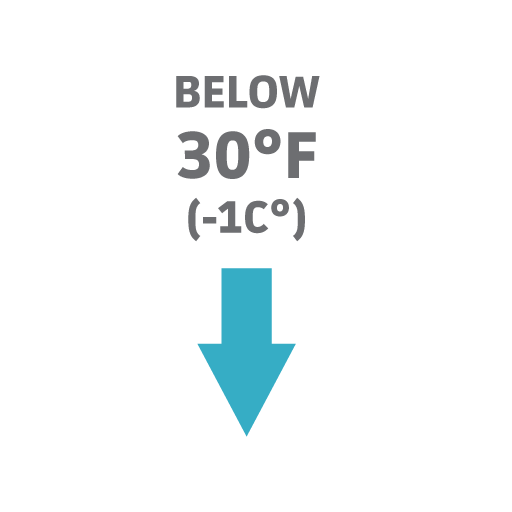

If temperatures are below 30°F., add Diesel Fuel Supplement +Cetane Boost (white bottle) for winter operability. It prevents fuel gelling and protects against fuel-filter icing.

In a winter emergency

Use Diesel 9•1•1 to reliquify gelled fuel and de-ice frozen fuel-filters if your vehicle will not start or gain power in cold weather.

At least quarterly or as needed

Treat with Clear-Diesel Fuel & Tank Cleaner to remove water, disperse contaminants and ensure fuel is stabilized for long-term storage.

If microbial contamination is present

Treat with Bio Kleen Diesel Fuel Biocide to kill the microbes and Clear-Diesel Fuel & Tank Cleaner to remove the residual water and contaminants.